What Screws To Use For Squeaky Flooring (Ultimate Guide)

You don’t call for to deal with squeaky floors whatever longer. There are measures you tin accept to make certain those annoying problem boards are no longer an result.

Screws have proven to be ane of the best fasteners to bargain alongside squeaky floors. We know the specific screws that are perfect for the chore, in addition to in one case y'all’ve read through this article, you lot volition also!

Screws are meliorate than nails to silence squeaky floors. ane¾”-iii” subfloor or floor screws are best. Deck screws as well as structure screws are also adequate. Steel together with galvanized steel are the best material. #viii to #12 sized screws are the best thickness. Fine threads create tight holds inwards simply are tedious to install.

Screws or Nails? Which Are Best?

For installation of subfloors, nails together with screws both function, just each comes alongside its own benefits together with drawbacks. In damage of squeaking, or rather, the prevention thereof, screws take proven to be the best choice.

Nails are the faster option since a nail gun industrial plant faster than a drill. They are likewise cheaper than screws. However, nails accept more than potential for squeaking than screws. With temperature changes, nails can drive squeaking due to crusade between the subfloor in addition to the boom. This is especially true in areas of high traffic period.

The speed in addition to inexpensiveness of nails is ofttimes very tempting to an overextended or sub-par contractor, so brand certain y'all know what’second happening amongst the installation of your wooden flooring.

If your contractor has tried to cutting corners as well as the upshot is a squeaking flooring, and then unless you lot signed a contract that specifically excludes fixing squeaking floors, and then this job should live covered nether your warranty.

Screws have longer overall since they demand to live twisted into place in addition to are often more expensive than nails. But screws are improve for preventing squeaking since they are less probable to loosen and take movement. Screws are solidly drilled into place in addition to the threads aid agree them where they are.

Subfloor vs Top Floor Screws (Is There a Difference?)

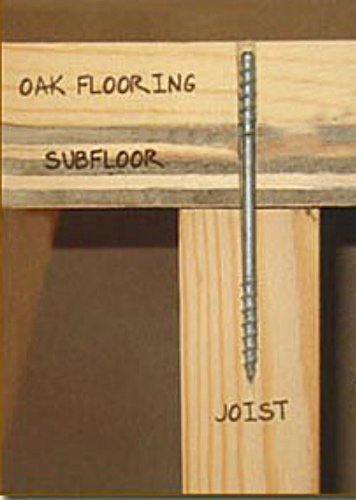

Subfloor screws differ from elevation flooring screws because the height floor screws’ heads volition be visible. Top flooring screws also necessitate to live somewhat longer than subfloor screws because they involve to drill downwards through the floor, subfloor, and into the joist below.

Make sure that top floor screws are longer than the length of the subfloor screw; that is an inch longer than the subfloor’second thickness, summation the thickness of the floor higher up. Installation of a peak floor screw power postulate cutting a hole in carpet.

The head of the tiptop floor screw volition live visible, and then it is wise to choose a mode of screw that is discrete or attractive. Certain types of screws come up amongst removable heads, but these are inadvisable since they are not equally potent every bit regular screws.

Best Screw Type

There are several types of screws that volition operate for subfloor installation together with make a adept job of preventing squeaking.

Subfloor/Flooring Screws

These screws are specifically designed to fasten subfloors securely together with trim down squeaking. These screws are oft i ¾” to iii″, which covers the length needed for virtually applications, too they are unremarkably covered inwards a zinc coating to resist corrosion.

These screws are made to be easily installed in addition to volition not split up the forest they’re drilled into.

Deck Screws

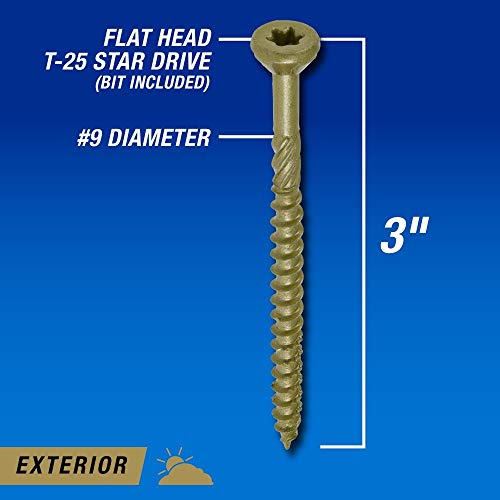

Deck screws are oftentimes used for subfloor installation amongst not bad success. These screws accept deep, sharp threads that create a tight hold inward the material. These screws are likewise sturdier than wood screws.

Deck screws are often made of stainless steel due to their mutual outdoor utilisation, as well as they operate from nigh one ¾” to three″.

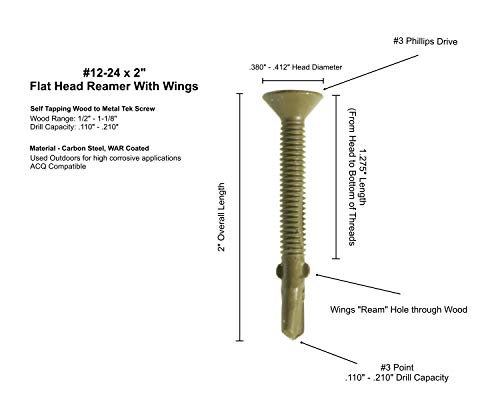

Construction Screws

Construction screws tin too live used for a subfloor due to their serrated threads, which permit y'all to use them without having to drill any holes starting time. Construction screws by and large work larger than deck screws as well as other alternatives, with 3″ beingness amid their lowest size options.

Don’t Use These Screws!

There are screws that are bang-up to function, those that are sufficiently capable of serving the job, too then those that should live actively avoided.

Drywall Screws

It is inadvisable to purpose drywall screws on subflooring since they are non potent plenty to handle the extensive bear on on the floor. When used for flooring, the heads of drywall screws often curve or snap off under the pressure, while more durable options are built to withstand this strain.

Kits

Some sources do non advise the role of squeak prevention kits. Although these are a tempting, all-in-1 pick for fixing your squeaky floors, they are not durable enough to supply a lasting solution. If yous want a quick temporary make yous tin attempt talcum pulverization instead.

These kits ordinarily come up amongst tear-away screw heads, designed to shroud screws inwards already finished flooring. But the problem with the kits is that they come loose in one case the screw heads are torn off.

Does the Material Make a Difference?

The best materials for subfloor screws are steel too galvanized steel. Both options render the necessary forcefulness as well as durability for the wear too tear of floor.

Steel is the nearly suitable cloth for screws to foreclose squeaking, since it is a stronger material than other screw types, including aluminum too brass. Galvanization gives steel screws the added benefit of beingness corrosion resistant by existence coated alongside a protective zinc trounce

Electroplated screws are suitable for indoor projects simply volition not weather good outside. The recommended screw material for outdoor projects is stainless steel.

There are several coatings other than zinc that tin can brand screws more than durable to withstand wet together with rust. Some of these different coatings include epoxy in addition to HCR, or Highly Corrosion Resistant coating.

Screw Size

Ideal Diameter for the Screws

Screws should be thick enough inwards diameter to hold the subfloor securely. With increasing numbers corresponding to increasing diameter. #eight-, #10-, and #12-sized screws volition all function for subfloor installation.

For the strongest screws, a thicker diameter is recommended, thus, #12 screws are the strongest choice for subfloor installation.

However, #eight is the standard size together with volition be effective for subfloor installation. This thickness is effective for near types of forest, in addition to alone heavier materials volition involve a higher thickness. Screws thinner than #viii will probable non concur upward well plenty to operate inward the subfloor application.

Thick screws stand upwardly good to upwardly together with downwards force per unit area (spell longer screws are improve for sideways force) like that of a pes stepping on the flooring.

Choosing the Right Length of Screw

Length is the most important mensurate of screw size for making certain your floor is attached well as well as won’t squeak. If screws are not long plenty, they will non live able to fulfill the chore of securing the subfloor to the joist beneath it.

Screws ask to extend about an inch by the plywood subfloor into the joist underneath it. Commonly, steel screws extend from near i ¼” to three″ or more than.

Most flooring experts will use 3″ screws for subfloor installation. This length volition ordinarily live at to the lowest degree equally long equally y'all volition call for, likely with some excess length since ¾” subfloor requires a one ¾” screw, a 5/viii″ subfloor volition need a 1 5/eight″ screw, too and then on.

What Type of Thread Creates the Tightest Join?

Screw threads come up alongside variations that alter how tight the screw is jump to the textile. A screw amongst a finer thread volition be a tighter bind than a screw alongside coarser threads.

Coarse threads hateful fewer threads along the screw, while fine threads hateful at that place are more than threads along the length of the screw.

Possible downsides of fine threaded screws are their speed of installation. These screws are slower to install than coarse threaded screws. They are likewise less usually used in applications. Coarse threaded screws are more than usually used even though they do not make as tight of an application.

Thread sharpness as well as length are as well factors to view. Sharper, longer threads are able to attach more than deeply to the forest and thence make a stronger attachment.

Certain screws take a small-scale thread about the head that allows you non to take to pre-drill a hole. An example of this type of screw is the Senco Duraspin, listed below.

Recommended Products

- Hard-to-Find Fastener Phillips Flat TwinFast Wood Screws (amazon link). These are cheap in addition to have a long lifespan, making them perfect for beginners or DIYers. These screws are coated inwards an attractive, rust as well as H2O-resistant dark phosphate complete.

- Senco Duraspin #8 Subfloor Collated Screw (amazon link). These Senco Duraspin screws are a bang-up selection since they are tardily to install too have smashing staying power. They come up alongside a xanthous zinc coating resistant to rust together with corrosion. They are ideally used inward tandem amongst the Senco Duraspin screw gun to greatly increase the speed of the process.

- Hillman Group Square Drive Flooring Screw (amazon link). These Hillman Square Drive Flooring screws as well boast beingness heavy-duty in addition to slowly-to-install options.

Silencing Squeaks Often Needs More Than Screws

If the joists are just not degree alongside the subfloor and gaps grade between them, these gaps will probable effort squeaking. This problem cannot be remedied by simply adding more screws.

One mode to tranquility a chronically squeaking floorboard is to add together a shim inward betwixt the floorboard in addition to the subfloor where they take separated. A sparse slice of forest should live covered inward carpenter gum as well as inserted underneath the lifted subfloor. Make sure not to force the shim inwards as well far, every bit this could cause fifty-fifty more than of the subfloor to get lifted.

If squeaking is caused by a longer gap along the length of the flooring joist, using a caulking gun to utilize adhesive inwards the gap can live an effective method to silence the squeak.

If you lot take warped joists beneath your subfloor, this tin effort gaps and squeaking. This problem tin can live remedied by installing long, degree boards along the joists where they are warped too non touch the subfloor. This volition give you lot a degree surface to screw the subfloor into and so at that place are no more than gaps.

If your downstairs neighbor is complaining almost squeaking floors, simply the issues is not fixable alongside screws, yous will take to brand arrangements alongside them to gain access to the underside of the floor through their ceiling.

This is a tricky affair to navigate if your neighbour is on the unreasonable or frustrated side. However, there are close to tips to approaching the situation, which I accept set out in my article: Downstairs Neighbor Complaining About Squeaky Floors.

Sources

https://www.nailgundepot.com/blog/installing-subfloors-nails-vs-screws.html

https://www.h2ouse.org/subfloor-screws/

DIY Squeaky Floor Fixes, You Should Avoid! (squeakknights.com)

https://toolsarchive.com/best-screws-for-subfloor/

https://www.hunker.com/12609071/the-differences-betwixt-a-deck-screw-a-structure-screw

https://www.nord-lock.com/insights/bolting-tips/2010/pick out-fine-or-coarse-thread-bolts/

https://www.angi.com/articles/how-silence-squeaking-floor.htm

0 Response to "What Screws To Use For Squeaky Flooring (Ultimate Guide)"

Post a Comment